Accelerated Bridge Construction - Faster, Safer, Better

12/15/2022

Utilizing Accelerated Bridge Construction (ABC) and precast, prestressed concrete elements and systems to repair or replace bridges and decking can create many efficiencies for state departments of transportation and other transportation agencies. Thereby enabling them to stretch their funding while effectively, efficiently, responsibly, and safely repairing aging infrastructure. Precast concrete is an excellent choice for accelerated bridge construction due to its speed, versatility, resiliency, and high quality. Precast is manufactured offsite in a PCI-Certified production plant under controlled environmental conditions. It can be quickly and efficiently erected on site and requires less maintenance over the bridge's lifetime.

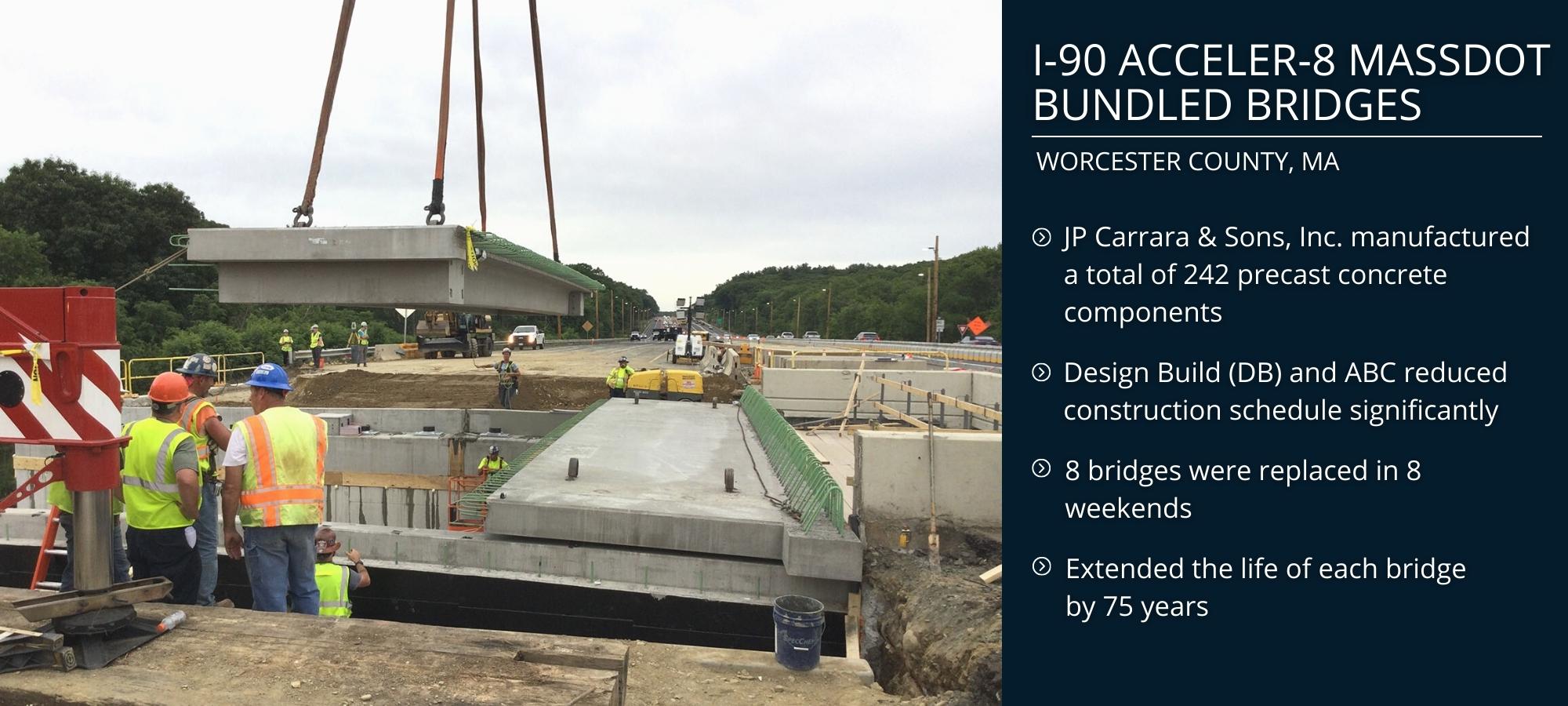

The Massachusetts Department of Transportation chose ABC to complete the

I-90 Acceler-8 Bundled Bridges project in Worcester County, demonstrating the use of precast concrete elements to provide safer and more efficient construction, reducing the schedule from several years to ONLY 8 weekends.

Learn more about the I-90 Acceler-8 Bridge Project in this Aspire Article

Why ABC and how it can help the Northeast Region

Learn more about the I-90 Acceler-8 Bridge Project in this Aspire Article

Why ABC and how it can help the Northeast Region

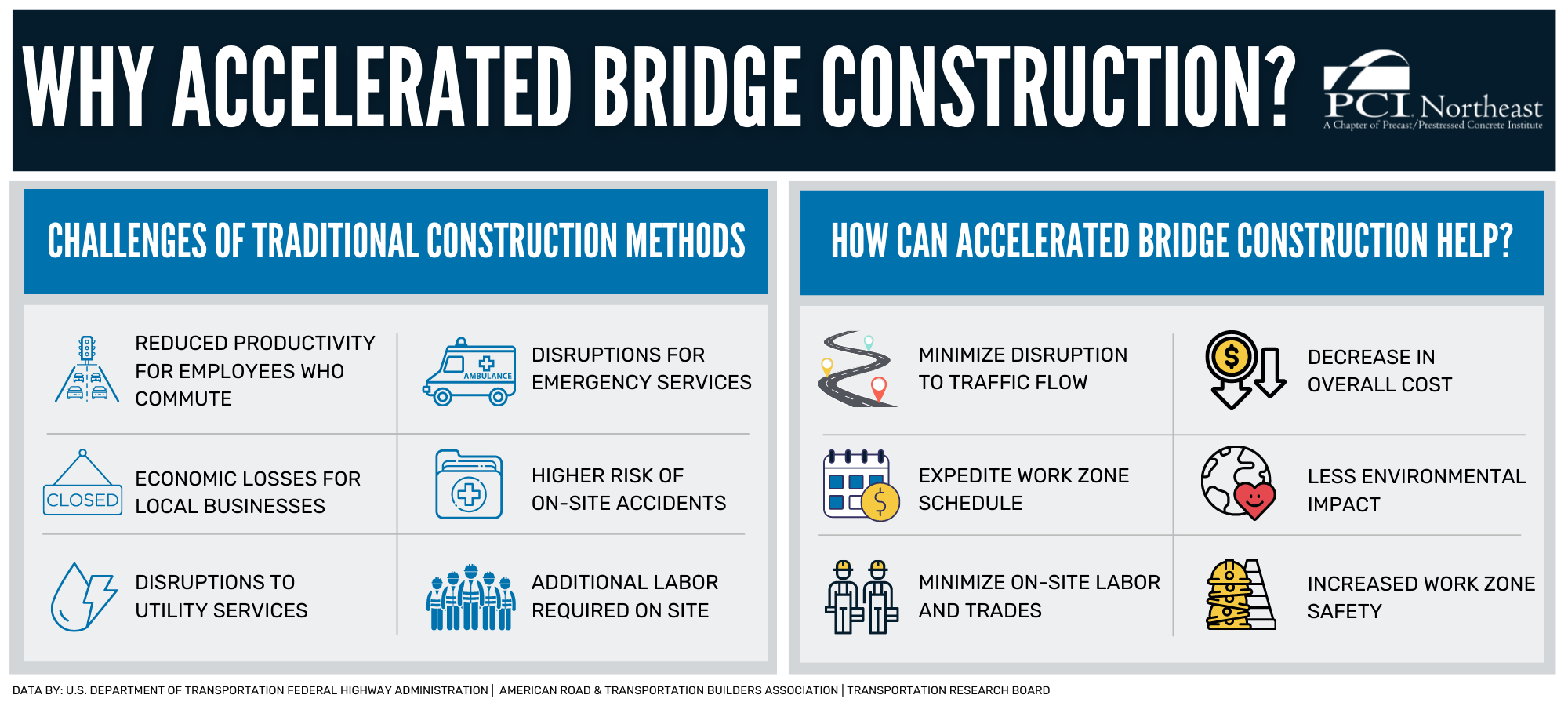

Bridge Construction that does not significantly reduce the onsite construction time required to build, replace, or rehabilitate a single or group of bridge projects is called conventional bridge construction. Conventional bridge construction methods entail time-consuming and weather-dependent onsite activities. These traditional construction methods include onsite installation of substructure and superstructure forms, accompanied by reinforcing steel placement, concrete placement, and concrete curing, all completed in sequential order. One reason to limit onsite construction activity is that the long-term presence of contractor-related equipment, labor, and staging areas can cause driver distractions and traffic disruptions, reducing the transportation network's safety and mobility efficiencies.

Because onsite construction-related activities directly affect the safety of the traveling public and the flow of the transportation network, reducing traffic impacts is a frequent rationale for using ABC. However, issues with site constructability are more frequent and good reasons to employ ABC. Long detours, the expensive use of temporary structures, remote site locations, and short construction windows often create situations where ABC offers more practical and cost-effective solutions than conventional construction methods.

PCI Northeast ABC Resources

PCI Northeast ABC Resources

As the chapter representing PCI-Certified precast concrete producers in the region, PCI Northeast has developed various resources to aid in designing, engineering, and constructing bridges utilizing ABC methods.

The PCI Northeast Bridge Technical Committee, a unique partnership comprised of state bridge engineers, consultants, and precast manufacturers from all six New England states and New York, has developed many resources for bridge construction in the Northeast. The resources are available on the PCI websites and are free to download. They include The Northeast Extreme Tee (NEXT) Beam, engineered to be labor-efficient in the plant and on the job site. Eliminating field deck forming saves considerable time during construction while providing an immediate work platform, resulting in a much safer project.

The Northeast Bulbtee (NEBT) is used for single or multi-span bridges up to 180 ft. It can also be constructed using splice girder technology for spans up to 250 ft.

Bridge Deck Panels are used to accelerate full-depth deck replacements, with length and width dictated by bridge geometry. There are several methods available to connect the panels in the field. Partial Depth Deck Panels or stay-in-place (SIP) forms are used to reduce deck forming. The remaining portion of the deck is comprised of CIP with precast form.

Guidelines for Precast Substructures used in ABC provide methods to connect precast for various substructure applications. The details promote greater uniformity in designing and constructing precast concrete substructure elements for bridges.

Case Studies

Replacement of I-89 Bridges , Colchester, VT

Engineers immediately chose precast concrete to accomplish the needed objectives of this project's tight deadline. It enabled rapid construction, which minimized the burden of travelers by restricting the project to six-weekend closures.

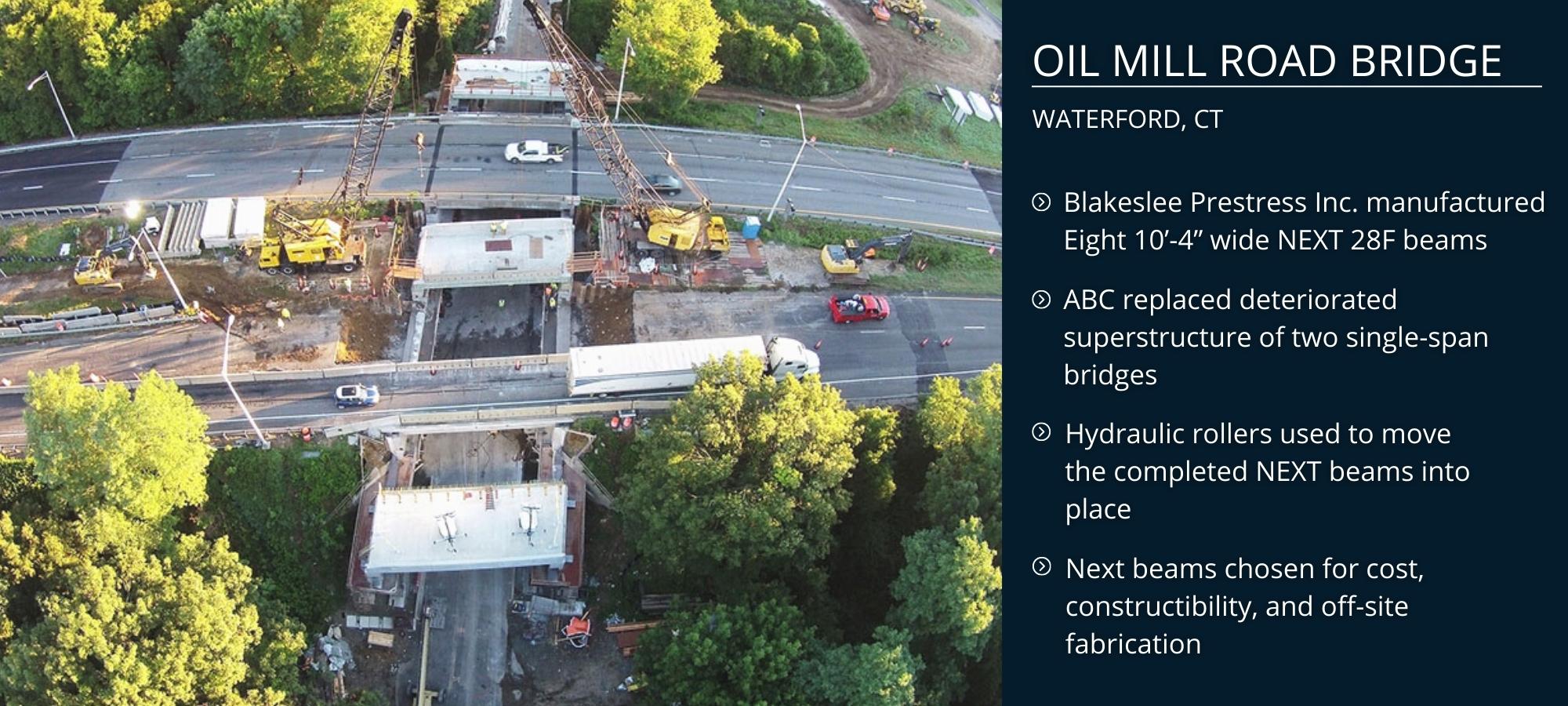

Oil Mill Road Bridge, Waterford, CT

The damaged superstructures of two-single span bridges that carry Interstate 95 over Oil Mill Road in Waterford, CT, were replaced using accelerated bridge construction (ABC) technology. The project was the first in the state to use hydraulic rollers to transport the final beam/slab assembly into place on the tracks.

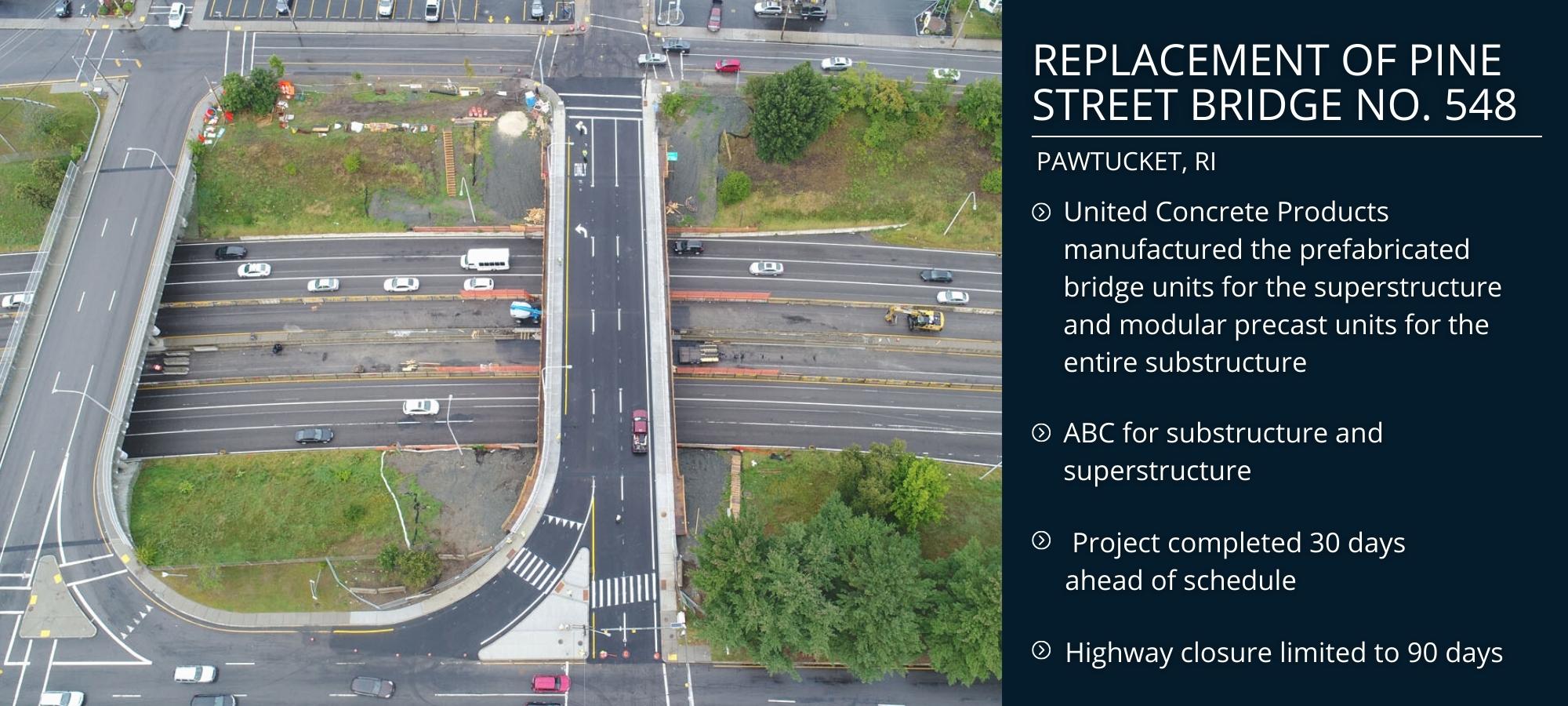

Replacement of Pine Street Bridge No. 548 , Pawtucket, RI

The damaged superstructures of two-single span bridges that carry Interstate 95 over Oil Mill Road in Waterford, CT, were replaced using accelerated bridge construction (ABC) technology. The project was the first in the state to use hydraulic rollers to transport the final beam/slab assembly into place on the tracks.

Replacement of Pine Street Bridge No. 548 , Pawtucket, RI

To speed up the replacement of Pine Street Bridge No. 548, The Rhode Island Department of Transportation employed accelerated bridge construction methods utilizing precast concrete components and pre-manufactured bridge units. Compared to conventional methods, the ABC approach rapidly constructed a new bridge deck and saved significant time.

Conclusion

The construction industry has used an accelerated bridge construction approach involving prefabricated precast/prestressed concrete road and bridge elements and systems for over two decades. Accelerated bridge construction is increasingly employed worldwide to construct malls, residences, highways, and bridges due to its benefits including enhanced worker safety, overall quality, and decreased inconvenience to the public.

Accelerated bridge construction entails prefabricating bridge components offsite and transporting them onsite for installation. High-quality PCI-Certified precast/prestressed concrete is ideal when constructing bridges with the ABC approach. Precast concrete paired with ABC has delivered faster, safer, and better bridges while alleviating many critical issues associated with conventional bridge construction.

Learn more about ABC with these Resources

Webinar Accelerated Bridge Construction using Precast Concrete

PCI Bridge Publications

On-Demand Transportation Courses